With the opening of science and technology and the continuous increase of the national economy and people's living standards, the demand and demand for various electrical products with multi-function and high quality are constantly increasing. The painting of electrical appliances should be used to the market competition at home and abroad and the demand for expanding demand.

1. Technical Features of Coating for Electrical Goods

Electrical products and their components are complex, and the amount of coating is large. There are various demands for the function and quality of the coating, and there are many types and types of coatings used. The demand for the coating quality and application environmental conditions of custom electrical products is simply the culmination of modern coating methods. The commodity coating has many technical features, which are summarized as follows:

1) Electrical function demand: the painting of various electrical products must be satisfied with the electrical function demand. Such as insulation, heat resistance, arc resistance, spark breakdown resistance, corrosion resistance, abrasion resistance, moisture resistance and mold resistance.

2) Protection: The environmental conditions for the application of electrical products after painting are various, so the appearance of the products needs to be protected. The external coating shall be resistant to damage caused by chemicals, solvents and a variety of corrosive media, and shall also have three prevention functions. The coating, coating thickness and function requirements are different for different degrees of protection. It should be different according to the environmental conditions of commodity use.

3) Decoration: the decoration required by the painting of electrical products varies from high to low. High decoration demands bright colors, full bright light, smooth and flat. The appearance of various electric control cabinets should be harmonious and soft in hue and brightness.

4) Excellent mechanical function: the coating of electrical products usually demands excellent mechanical function. The coating shall be tough and wear-resistant, and resistant to mechanical and artificial damage such as impact and bump. The coating shall have excellent adhesion to the appearance of the commodity. Due to the poor application environment conditions of some commodities, such as the short hardness and strength of the coating, the service life of commodities will be greatly reduced.

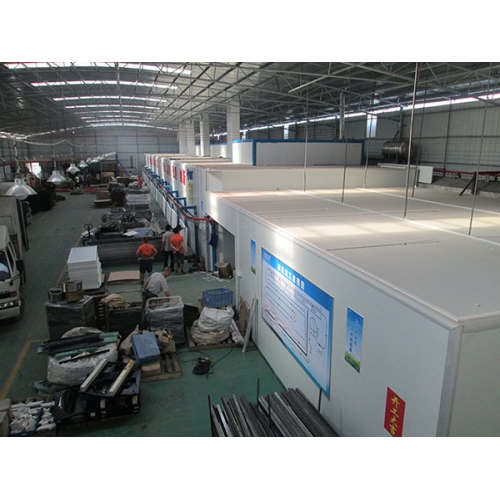

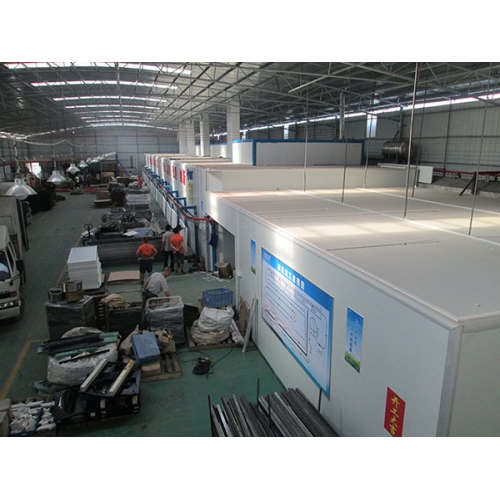

5) Production of mechanized and automated coating: the mechanized and automated assembly lines produced by electrical operation coating are extremely extensive, which is due to the large amount of electrical commodity coating. And the shape, standard and batch of most commodities have the conditions of automatic flow painting. New equipment and new technology produced by modern painting are widely used, and the technical and economic benefits of painting are high. The introduction, digestion and absorption of foreign preemptive coating technology have been carried out rapidly in electrical work. The open trend of modern painting technology with high efficiency, low consumption, energy saving, reduction or elimination of environmental pollution, and improvement of working conditions produced by painting has achieved outstanding performance in the painting of electrical goods, and will soon be widely used in all mechanical operations.

2. Type of coating required for electrical products

There are many types of coatings used in the production of electrical appliances, including solvent based coatings, electrophoretic and powder coatings, and many art based coatings.

3. Coating technology of electrical products

Nowadays, it is mostly produced for mechanized automatic flow painting. There are primary technical methods such as manual automatic line spraying, electrophoresis, electrostatic spraying and powder electrostatic spraying.

Spray processing , Huadu spray processing , Guangzhou spray processing Which one is good? The first choice is Tuoshen Surface Treatment Co., Ltd., which is worthy of your trust. Welcome to inquire!