Replacing traditional solvent based coatings with water-based coatings can significantly reduce the emission of volatile organic compounds (VOC) in the automotive coating process. It is an environmentally friendly coating process being vigorously promoted in the automotive industry. This paper introduces in detail the actual design and application of water-based paint spraying system in automobile painting in China.

[Key words] Environmental protection of water-based paint for automobile coating

0. Preface

Since the reform and opening up, China's economy has grown rapidly, and great achievements have been made in various economic construction, but it has also paid a great price for resources and environment. The contradiction between economic development and resources and environment has become increasingly acute, and the people have a strong response to environmental pollution. In the 11th Five Year Plan, China clearly put forward the development goal of "implementing the basic national policy of saving resources and protecting the environment, building a national economic system with low input, high output, low consumption, low emissions, recyclable and sustainable, and a resource-saving and environment-friendly society". On August 15, 2006, the National Environmental Protection Administration issued the "Clean Production Standard for Automotive Painting", and stipulated that it would be implemented from December 1, 2006 to control the generation of pollutants from the source of production, rather than focusing on how to deal with pollutants.

In the automobile manufacturing process, the painting workshop is the production workshop with the largest emissions of three wastes. Therefore, in recent years, driven by the relevant laws and regulations of automobile manufacturing, reducing the pollution of painting, reducing the cost of painting and improving the quality of painting have always been the theme of the development of automobile painting technology. How to reduce the emission of volatile organic compounds (VOC) in the process of automobile painting is one of the main research topics of automobile painting technology.

At present, most domestic automobile coating production lines still adopt the process system of solvent based intermediate coating+solvent based surface coating primer+one component varnish, VOC emission is up to 120g/m2, which is far higher than the basic requirement of 3C3B coating level III standard VOC emission ≤ 80g/m2 in the Clean Production Standard for Automotive Painting, and is far worse than the requirement of the international advanced level level I standard VOC emission ≤ 40g/m2 specified in the standard. The water-based paint coating process can control pollutants from the source and significantly reduce VOC emissions during the coating process. It is an environmentally friendly coating process that is being vigorously promoted.

The coating workshop of SAIC Lingang Industrial Base is jointly developed and built by SAIC Motor Corporation Limited and the Fourth Design and Research Institute of Machinery Industry. It has the world's advanced level in safety, environmental protection, energy conservation and other aspects. Its products are the high-end cars of the "Rongwei" series of SAIC's own brand. SAIC Lingang Coating Workshop has used water-based coatings in the intermediate and surface coating process. The coating process is water-based intermediate coating+water-based base finish paint+two-component varnish, which can make VOC emissions less than 40g/m2, reaching the international advanced level of cleaner production.

This paper briefly introduces the practical application of water-based paint spraying system in the project of Lingang painting workshop.

1. Characteristics of water-based paint

Traditional solvent based coatings use organic solvents as dispersion medium and diluent, while water-based coatings use water as dispersion medium and diluent. The difference in characteristics between water and solvent as dispersion medium and diluent of coatings is mainly shown in:

1.1 Volatility difference: water is more difficult to volatilize, and it is easy to cause sagging of paint film under high humidity conditions.

1.2 Surface tension difference: the surface tension of water is higher than that of solvent, and the surface quality of finished paint film will be affected if the paint is not adjusted.

1.3 Conductivity difference: the conductivity of water is much higher than that of solvent, which will affect electrostatic spraying.

1.4 Difference in viscosity characteristics: the viscosity of water varies greatly under the influence of shearing force. When subjected to high shearing force, the viscosity of water-based paint will drop a lot, which will have a great impact on the paint conveying and mixing system.

1.5 Difference in corrosivity to metal materials: water is highly corrosive to metal materials, which will cause corrosion to the coating equipment in contact with it.

It is precisely because of the above different characteristics of water and solvent that the difference between water-based paint and solvent paint in many aspects is caused, which also leads to the need for different equipment systems to adapt to water-based paint and traditional solvent paint during spraying construction.

2. Construction process window of water-based coating

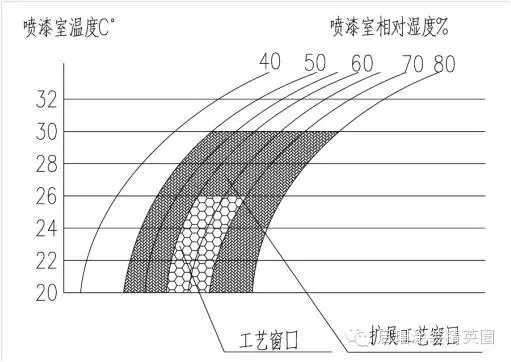

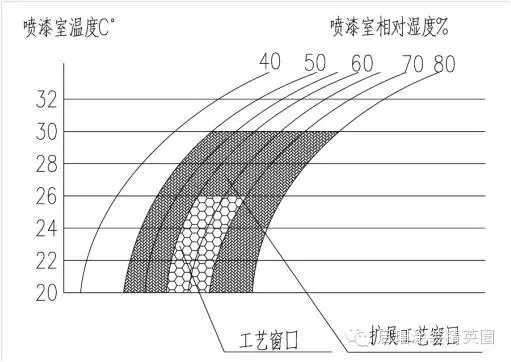

The coating construction process window refers to an approximate quadrangle formed by the upper and lower limits of the environmental temperature and humidity requirements that must be met for the coating construction, which is the basic input condition that must be met for the design of the paint spraying equipment system. Compared with the relatively loose construction process window of traditional solvent based coatings, water-based coatings have more stringent requirements on the ambient temperature and humidity conditions for spraying. Generally, the construction temperature of water-based coatings is 20 ℃~26 ℃, and the humidity is 60%~70%. However, in order to select a coating supplier with greater margin and better guarantee the production quality, The window conditions set during the design of the paint spraying equipment system should be more strict, generally meeting the control accuracy requirements of temperature 23 ± 1 ℃ and humidity 65 ± 3%.

Figure 1 Construction Process Window of Waterborne Paint

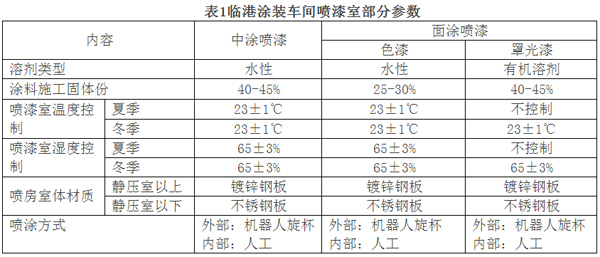

3. Paint booth system for middle surface coating

The intermediate and surface painting room system is the workplace and equipment used to complete the intermediate and surface painting construction. The system needs to have two main functions: one is to provide the best painting environment conditions according to the requirements of the spraying process; Second, it can timely capture the overspray fog generated in the spraying process and discharge the exhaust gas after washing, so as to prevent pollution of the working environment and the coating surface. The spray booth system is generally composed of the spray booth body, air supply system, paint mist capture and washing system, circulating water system, exhaust system and paint slag treatment system.

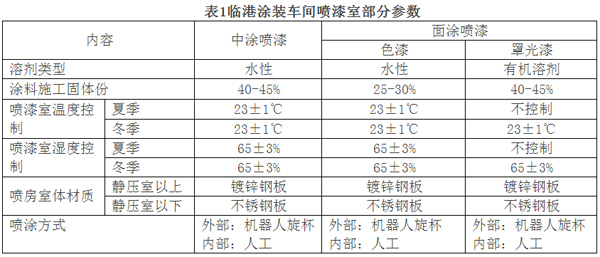

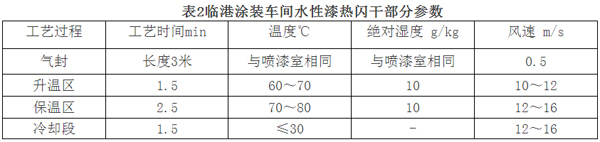

The design parameters of ambient temperature and humidity for painting in the harbor painting workshop: the temperature is 23 ± 1 ℃, and the humidity is 65 ± 3%. See the table below for details. The coating adopts the products of DuPont and PPG.

According to the test results in production, the actual set values of the paint booth in the port painting workshop are: the temperature is 22 ℃± 1 ℃, and the humidity is 60 ± 3%; The measured values are: the temperature is 21 ℃~23 ℃, the humidity is 59%~61%, which fully meets the requirements of the construction process window proposed by the above water-based coating supplier, and realizes the high quality of water-based coating construction.

4. Intermediate coating drying system

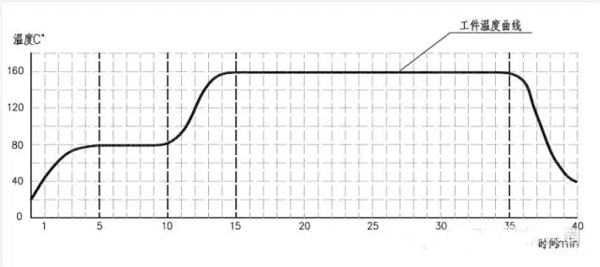

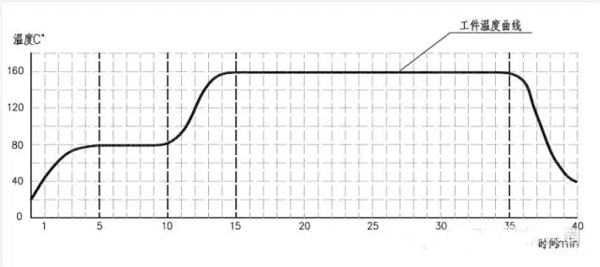

Different from the drying after the traditional solvent based intermediate coating construction, due to the low volatility of water, drying directly at high temperature after the construction of water-based intermediate coating will produce bubbles and other defects, so it is necessary to carry out low temperature pre drying, that is, hold at 80 ℃ for 5 minutes, make the water in the coating fully evaporate, and then heat up to 160 ℃ for 20 minutes to complete the curing of the coating film.

The temperature curve of drying workpiece for water-based intermediate coating is shown in the following figure:

Fig. 2 Temperature Curve of Drying Workpiece for Waterborne Intermediate Coating

The π type intermediate coating drying furnace is used in the harbor painting workshop. The heating is divided into three functional areas, namely, pre drying, temperature rise, and thermal insulation. Radiation heating is used in the pre drying area and temperature rise area, and hot air circulation heating is used in the thermal insulation area. The combination of radiation and hot air circulation makes the temperature rise curve of the workpiece meet the drying process requirements and improve the cleanliness of the drying furnace, ensuring the high quality of the intermediate coating film.

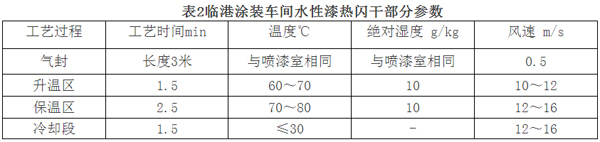

5. Hot flash drying system for water-based surface coating primer

For the solvent based finish coating process, the top coat primer and varnish are solvent based paints. After the primer is sprayed, the varnish can be directly sprayed after only a few minutes of leveling at room temperature. In the water-based paint finishing process, due to the difficult volatility of water, it is necessary to fully evaporate the water in the water-based base paint by heating and drying before spraying the finishing paint, so as to spray the next finishing varnish. Otherwise, bubbles will occur when the finishing paint is dried.

The thermal flash drying system of water-based surface coating base paint is used to heat and bake the base paint after the water-based surface coating base paint is sprayed and before the finishing varnish is sprayed, so as to make the dehydration rate reach more than 90%, and ensure the film forming quality of the surface coating.

As the key of water-based surface coating process, the core of hot flash drying system is the temperature and humidity control of heating circulating air system. The harbor painting workshop divides the hot flash dry section into one temperature rise zone and two insulation zones, and precisely controls the temperature and humidity of each zone, ensuring the dehydration rate index of the base paint before the finish varnish is sprayed.

6. Paint circulation system

The coating circulation system is a pipeline supply system that delivers the coating to the painting station at a certain pressure and flow, and controls and maintains appropriate coating process parameters during the coating operation. It includes central paint supply equipment, temperature control system, gun station outlet components and pipelines. Due to the difference of viscosity characteristics between water-based paint and solvent based paint, the difference of coating circulation system is caused. The key points of coating circulation system in port painting workshop are as follows:

·Stainless steel material shall be used to avoid the corrosion of the paint on the circulating system equipment and pipelines;

·Hydraulic power system is adopted to ensure the stability of paint supply pressure;

·Low shear equipment is used to eliminate the influence of viscosity characteristics of water-based paint on paint characteristics;

·Special liquid level control system is adopted to ensure stable supply of paint and avoid drying;

·High precision temperature control system is adopted to ensure high stability of coating temperature;

·Pure water filling system.

7. Robot automatic electrostatic spraying system

High voltage electrostatic rotating cup spraying is to take the high-voltage electrostatic rotating cup as the negative pole and the grounded coating material as the positive pole, and form negatively charged atomized particles of the coating material to evenly paint on the surface of the coating material under the action of the electric field force. Due to the conductive characteristics of water-based coatings, the electrified coatings must be insulated from the coatings in the circulating pipeline before the electrified construction. Generally, the electrified methods can be divided into external electrification and internal electrification. External power on refers to the way to power on the paint through external power on fingers. Its disadvantage is that external power on fingers are easy to be polluted, and are sensitive to the moving speed of the rotating cup and environmental humidity, which will reduce the spraying efficiency and affect the appearance quality of the paint film. It is more suitable for the project of using water-based paint to transform the existing solvent based paint; There are two types of internal power supply. One is to integrate the paint tank inside the robot arm. Before each spraying, the paint is injected into the paint tank for power up and then spraying. The other is to inject the paint into the special paint tank. The robot takes one paint tank for spraying each time. After spraying, the empty tank is put back to refill the paint. The robot takes another paint tank for spraying at the same time, This method is also called "magazine type paint supply system".

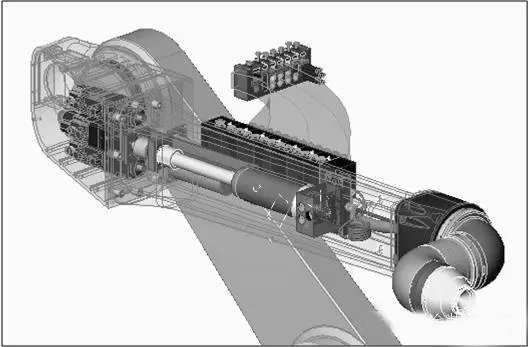

The Lingang painting workshop adopts the latest P500 wall mounted robot automatic electrostatic spraying system of FANUC, equipped with the water paint power on module and Versabell II rotating cup of FANUC's zhuanli technology. It adopts the internal power on method of integrating the paint tank inside the robot arm, which has the advantages of simple structure, convenient maintenance, low cost, etc, The spraying efficiency can reach more than 80%.

Fig. 5 P-500 Waterborne Paint Power on Assembly

8. Conclusion

Through the comprehensive inspection of the paint film performance of the products in the port painting workshop, including the appearance indicators (gloss, freshness, evenness, color, etc.), mechanical properties (adhesion, strength, scrub resistance, high-pressure cleaning resistance, etc.), stone impact resistance, water resistance, chemical media resistance (acid, alkali, automotive chemicals, solvents, etc.), corrosion resistance, aging resistance A series of tests, such as temperature change resistance, have proved that the quality performance of water-based paint film has fully reached or exceeded the quality performance index of solvent based coating.

In recent years, water-based paint coating process has been widely used in the coating line of European and American automobile industry, and has gradually become the mainstream in domestic joint venture automobile factories, such as Shanghai GM, Beijing Benz, Beijing Hyundai, Tianjin Toyota, Guangzhou Toyota, Guangzhou Honda Dongfeng Nissan and other joint ventures have begun to replace the traditional solvent paint coating process with water-based paint coating process.

SAIC Lingang Industrial Base, as the first batch of domestic enterprises adopting water-based paint coating process, has become the pioneer of energy conservation and environmental protection in China's own brand automobile factories. The successful implementation of this project has achieved SAIC's construction goal of "high quality and low cost", and has played a certain demonstration effect for the promotion of water-based paint coating technology in domestic independent brand automobile enterprises.

Guangzhou Tuoshen Surface Treatment Co., Ltd., the spraying manufacturer, is preferred for purchasing spraying, Spray processing Factory, trustworthy