Difference between plastic spraying and painting

(1) Primer (primer, primer)

Quality - SPC, six sigma, TS16949, MSA, FMEA primer is the first coating applied on the base course. It penetrates into the interior of the substrate, enhances the strength of the substrate, seals the surface of the substrate, eliminates the factors that damage the adhesion of the coating on the surface of the substrate, and increases the bonding force between the skeleton and the substrate.

(2) Intermediate layer (intermediate coating, skeleton)

Intermediate coating is a special forming layer of plastic spraying coating, and is the main component of plastic spraying coating. A special large caliber spray gun is used to spray on the base oil, and then rolled to form a three-dimensional pattern with rich texture and novel beauty. The skeleton has sufficient bonding strength and plays a role in reinforcing the building. At the same time, the skeleton is the main component of the plastic spraying coating, which increases the durability, water resistance and strength of the plastic spraying coating. Six Sigma Quality Forum

(3) Surface oil (surface coating, finish paint)

Six Sigma Quality Forum Topcoat is the surface layer of plastic spray paint. Various sun resistant color pigments are added to the surface oil, so that the plastic sprayed coating has a soft color. According to the different needs of indoor and outdoor, it can be sprayed into bright and flat coatings. The surface oil can beautify the surface of the plastic spraying coating and improve the durability of the coating.

Spray painting and plastic spraying are the main ways of industrial surface decoration nowadays. In order to protect the environment, we invented spray molding in 1982. After 20 years of development, no more than 5% of enterprises now use spray molding. Mainly due to the difference between painting and plastic spraying:

● Painting is better than leveling of plastic spraying.

The molecular structure of the solvents, additives and resins used for paint spraying is very helpful for leveling. However, there is no spray molding, so it often has an orange effect.

● Paint can be repaired.

In the process of painting, the pockmarks or scratches caused by excessive gas film can be repaired at any time, because the paint has the function of recoating. Spraying is not good.

● The flexibility (bending) of paint spraying is better than that of plastic spraying.

Paint can be bent 1mm, or even T bent, but plastic spraying is not.

● The painting is rich in decoration.

The appearance color of spray painting is dozens of times more than that of plastic spraying, and the same material can be made into different effects. For example, non-metallic materials such as plastic, wood, paper, cloth and leather can be made into aluminum.

● The hardness of painting is the same as that of plastic spraying.

● The pretreatment cost of plastic spraying is low and faster than that of plastic spraying.

● Spray molding must be baked at high temperature.

Plastic, wood, paper, cloth and leather cannot be baked at high temperature.

● Fast paint delivery, even if it is a small batch or special requirements, it can meet customer orders to the greatest extent.

● Compared with plastic spraying, the surface quality of painting is easier to overcome the defects of substrate and meet the customer's quality requirements. If the plastic spraying surface is not properly treated, it is easier to produce pitting defects (bubbles).

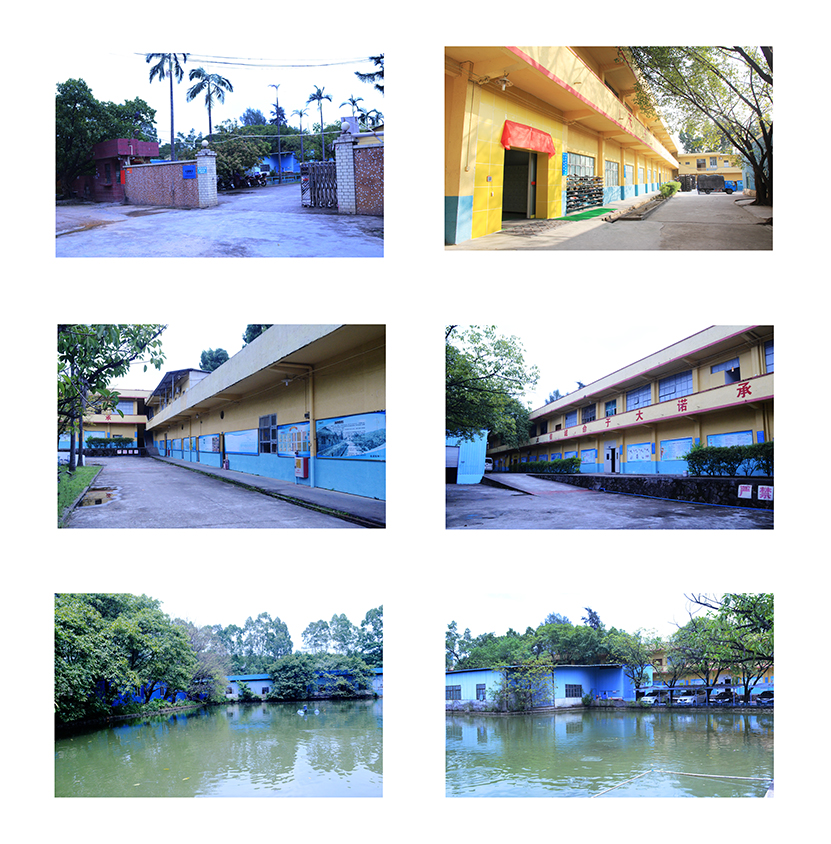

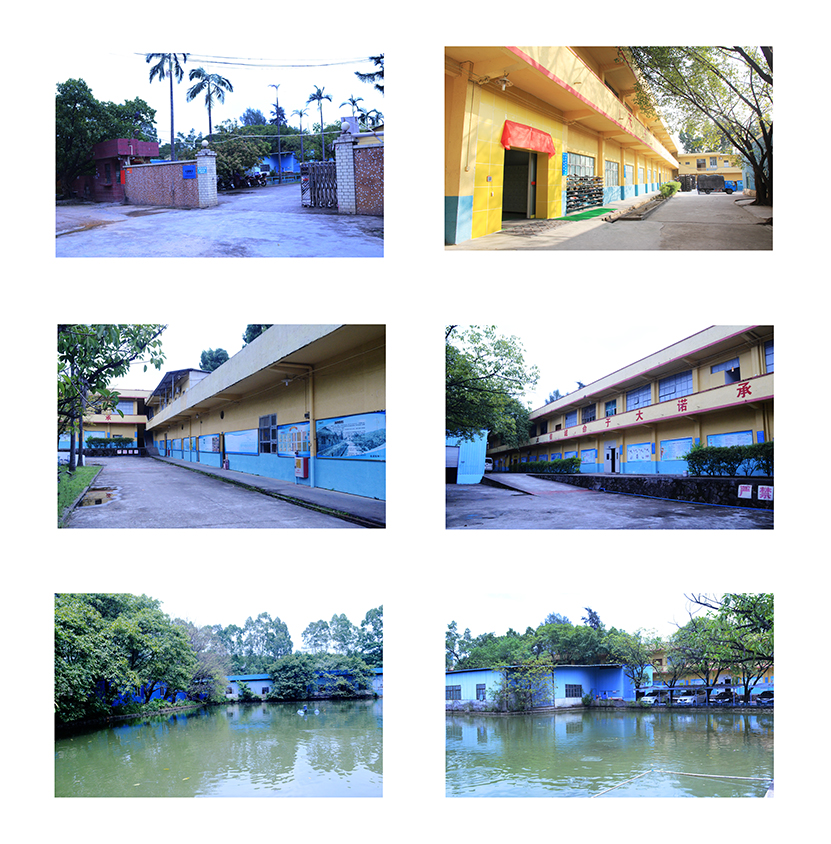

Spray processing , Guangzhou spray processing , Huadu spray processing First, Guangzhou Tuoshen Surface Treatment Co., Ltd. Guangzhou Tuoshen is trustworthy.