Decorative surface treatment technology refers to decorating the product surface with different colors, materials, surface treatment methods and various combinations, so that the product can attract different consumers in a unique and personalized way. Decoration can enhance the value of industrial products and commodities. Product surface decoration involves mechanical properties (such as hardness, sliding, etc.), electrical properties (such as conductivity, electromagnetic wave shielding, semiconductor properties), painting (metal color can make products have a high sense), color, texture treatment, etc.

With the appearance design and texture of industrial products becoming more and more exquisite and fashionable, the introduction of scientific and technological aesthetics to enhance value is the key to the next stage of industrial development. Surface treatment has always been regarded as "industrial product makeup artist". Through the continuous innovation of decorative surface treatment technology, improving the product surface appearance can effectively meet the increasing demand of consumers for creativity and aesthetic feeling, and inject a new vitality into the aesthetic economy.

Development Trend of Several Decorative Surface Treatment Technologies

1. Film

According to the data released by Fuji Economy, the scale of film decoration applied to smart phones, tablets, auto parts, consumer products, etc. will further expand. The main development trends of film decoration are as follows:

1) Film bonding and transfer decoration technology has been expanding.

2) Film substrates are developing day by day, such as MMA, easy forming PET, etc.

3) The function of film decoration is increasingly improved, and many manufacturers introduce diversified and multi-functional films.

4) Diversified design, such as printing, color injection, painting, steam plating, etc.

5) IML/IMD molding technology has been further developed, and double-sided bonding has been developed.

6) 3D transfer decoration technology has been widely used to meet the needs of different shapes and diversification.

2.3D digital texture bite

1) Background

The mainstream production method of traditional mold bite pattern is to form patterns on the completed mold by etching. However, the traditional undercutting method, which makes the mold locally corroded to form concave and convex, cannot produce deeper concave and convex. In addition, the final embossing depends on the intuition and skills of the craftsman, and it is difficult to predict the final completion. However, if the undercutting process is outsourced, there will be many restrictions on the degree of freedom of design. For example, most cases are based on the model prepared by the undercutting manufacturer, so it is difficult to produce innovative patterns.

2) Advantages and Applications of 3D Digital Texture Biting

3D texture can form three-dimensional texture of arbitrary height not only on the plane, but also on the surface. This technology uses digital tools such as 3D scanner and 3D model making software "Freeform" to make texture data, and then adds it to the CAD/CAM data of the product to make the mold. Because the texture is directly carved on the mold, only one resin molding can form a 3D texture with rich texture.

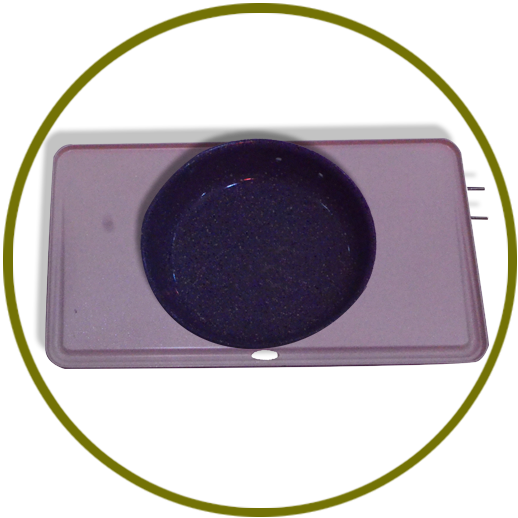

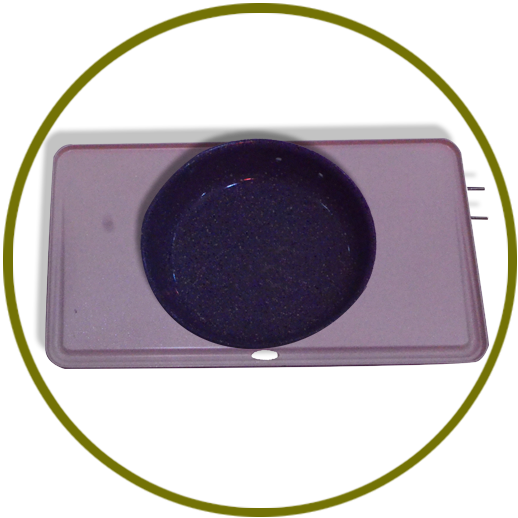

3D texture technology is used to make iPhone protective cases. 3D texture provides a series of processes to develop new patterns through digital data and apply them to resin molding products.

Not only injection molding, but also blow molding packing The development can also easily realize the complex texture that has not existed before. In addition to only replacing the mold with textured surface, it provides customers with the service of adding rich textures on existing shaped bottles at a low cost. By combining with other processing technologies such as resin materials and in mold molding, 3D texture technology will bring more excellent expression, including coloring and texture.

3. Color bionics

Color bionics is that human products imitate the color of natural creatures, such as natural beetles, soap bubbles, stones, etc. Color bionics is based on the spectral range of visible light of human eyes, and the material surface is perceived by human eyes due to the reflection of light. Similar to texture bionics, color bionics is physiologically dependent on human sensory perception, but its essence lies in the symbolic meaning of psychological perception.

Here are some film products made by color bionic technology:

1) Nano multilayers

Metallic, butterfly, and other color representations, such as Toray PICASUS. PICASUS and adoption electroplate Different from the film by evaporation, no metal is used at all, so there is no need to worry about rust or peeling. It is not only convenient for recycling, but also solves the environmental protection problems of electroplating plants.

In addition, when the light shines from the inside, the light can pass through, so text and graphics can be displayed. It usually has a metallic luster, and can be used for door handles, switch boards, instrument panels, etc. that only display text when necessary. The trade name is "flash stainless steel". The film alternately overlaps PET (polyethylene terephthalate) with higher refractive index and PET with lower refractive index to form a laminated structure of about 1000 layers. The overall thickness is 200 μ m. If only 1000 layers are calculated, the thickness of each layer is about 0.2 μ m. However, the thickness of the layers is not the same, but thin at one end and thick at the other, with continuous and equispaced alternate distribution. When the layer reaches a certain thickness, the color will appear due to the interference of light. When the evenly spaced distribution is adopted, all visible light can be reflected evenly, so it presents a metallic luster.

Extrude material from 500 nozzles distributed like combs. The nozzles of high refractive index PET and low refractive index PET are interlaced to form a "comb" shape. The two resins are extruded in a staggered manner to form a thick film. Two color forming is not adopted, but "thousand color forming" is adopted. It is thinned to 200 μ m after extension.

Put the film made above in the mold to form, and finally make the product. A certain degree of stretching can be carried out to make a surface in the preparatory forming stage. However, when the tensile strength exceeds 150%, each layer will become thinner, and the reflection wavelength will deviate, resulting in a pale green color.

2) Multilayer film deposition

Thin wall vacuum coating produces rainbow color, which changes when viewed from different directions. Such as Tsuda Industry.

3) Pattern decoration of random rough surface

4) Bionic color coating

Spray processing , Guangzhou spray processing , Huadu spray processing Which one is good? Guangzhou Tuoshen Surface Treatment Co., Ltd. is the first choice. It is trustworthy. Welcome to inquire!